I’m member of a number of Facebook groups for my hobbies including a couple for my Akai sampler. One of the funny things I read at some point in time, was when a guy reported that he “accidentally” bought another sampler 🙂 Well, seems I laughed a bit too soon as I’m now the proud owner of an S1000 I didn’t intend to buy.

This all started with a guy from Portugal who bought a used but defective S1000. In the end, he didn’t have time available to repair it and wanted to get rid of it. At some point he lowered the price to a (for me) interesting level and after some negotiations, we agreed on a total price including shipping with my intention to have a quick look to see if it was repairable, don’t spend too much money on it and otherwise part it out for spares if it became too costly.

The sampler was made ready for shipment (thanks Paulo for arranging this) and after a European tour from Portugal to Spain, Italy and Belgium, finally arrived in The Netherlands at my home.

Right, first thing to do was to unwrap it and to do a physical inspection. The outside case was not in a great condition and looks like someone had kept it in a humid shed.

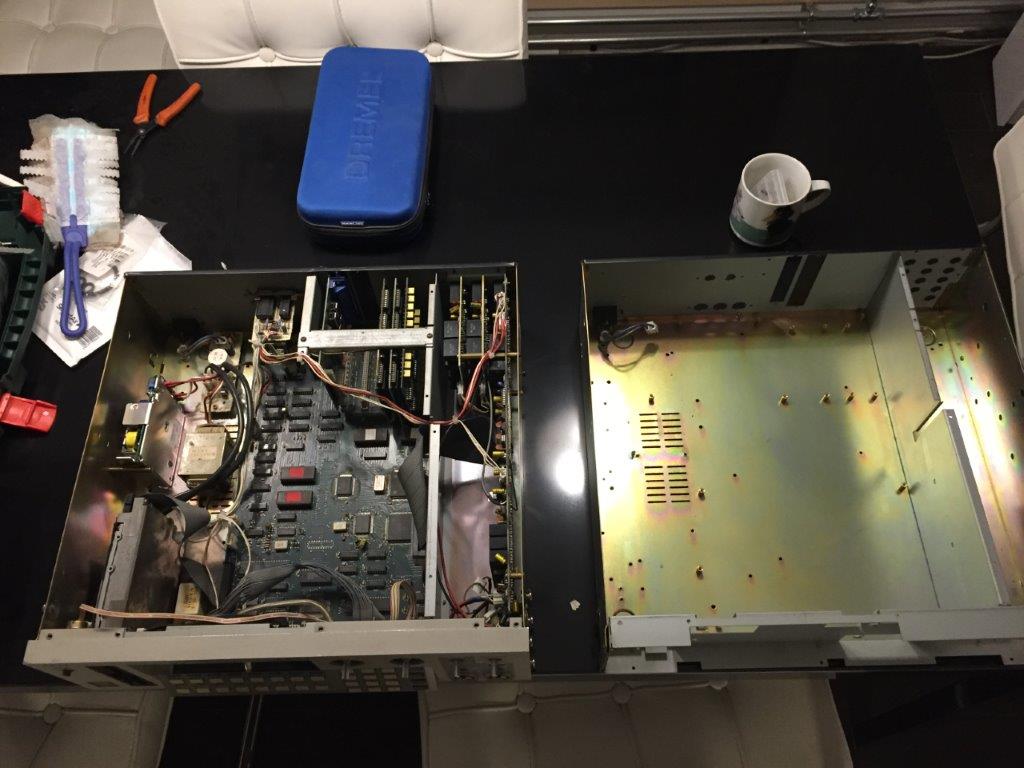

The inside wasn’t too bad with the electronics looking decent. First problem was that the power button was sticking which was easily fixed by disassembling it from the front panel and reassembling it again.

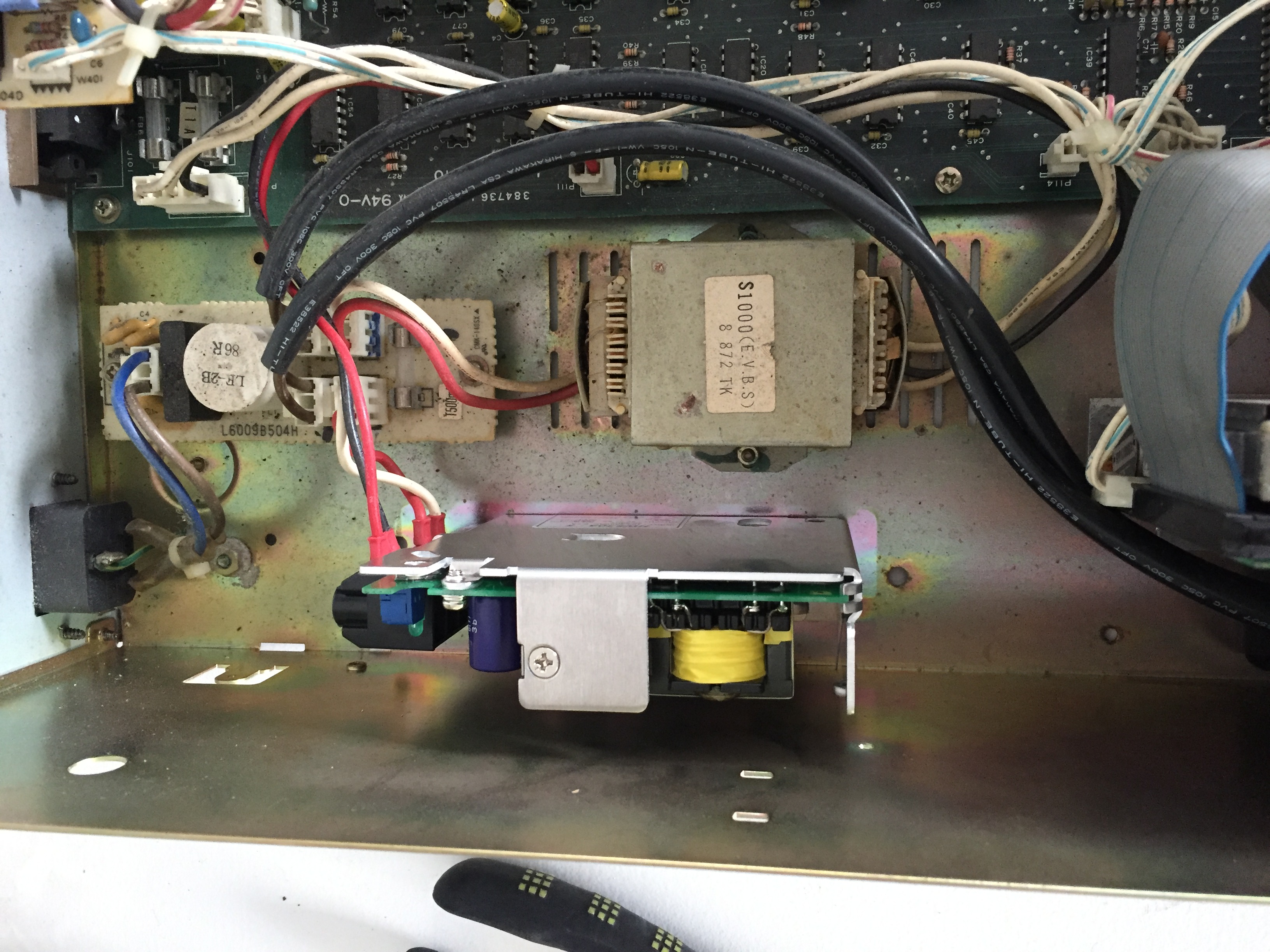

Powered it on, absolutely nothing. Right, time to break out the multi meter. This Akai actually has 2 power supplies with a switching power regulator for 5V and a standard one for the 12V. The 5V supply was dead as a doornail, got my laboratory power supply (big 10A adjustable supply) to see if this was the only issue at this point.

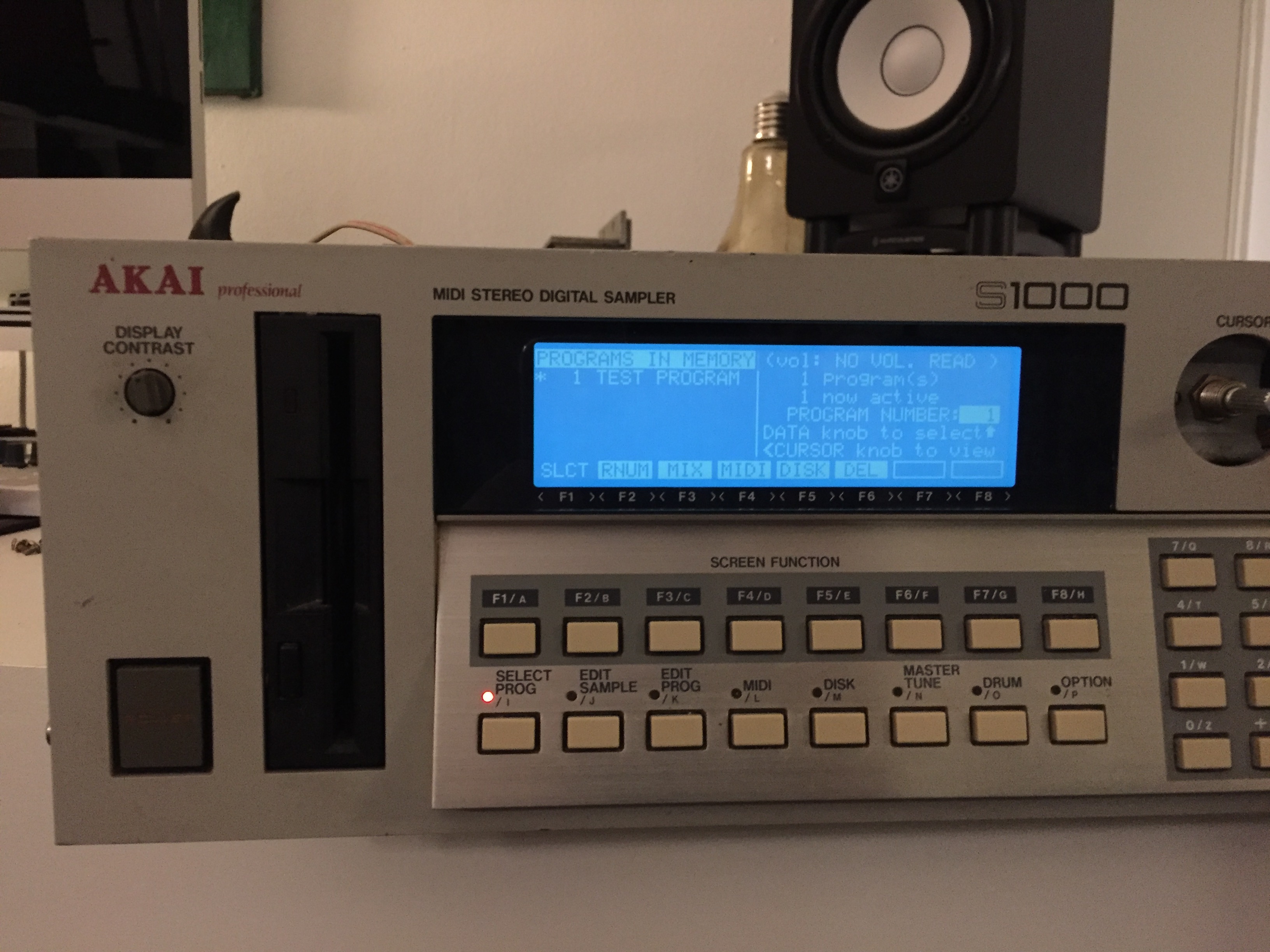

And low and behold…it powered up!

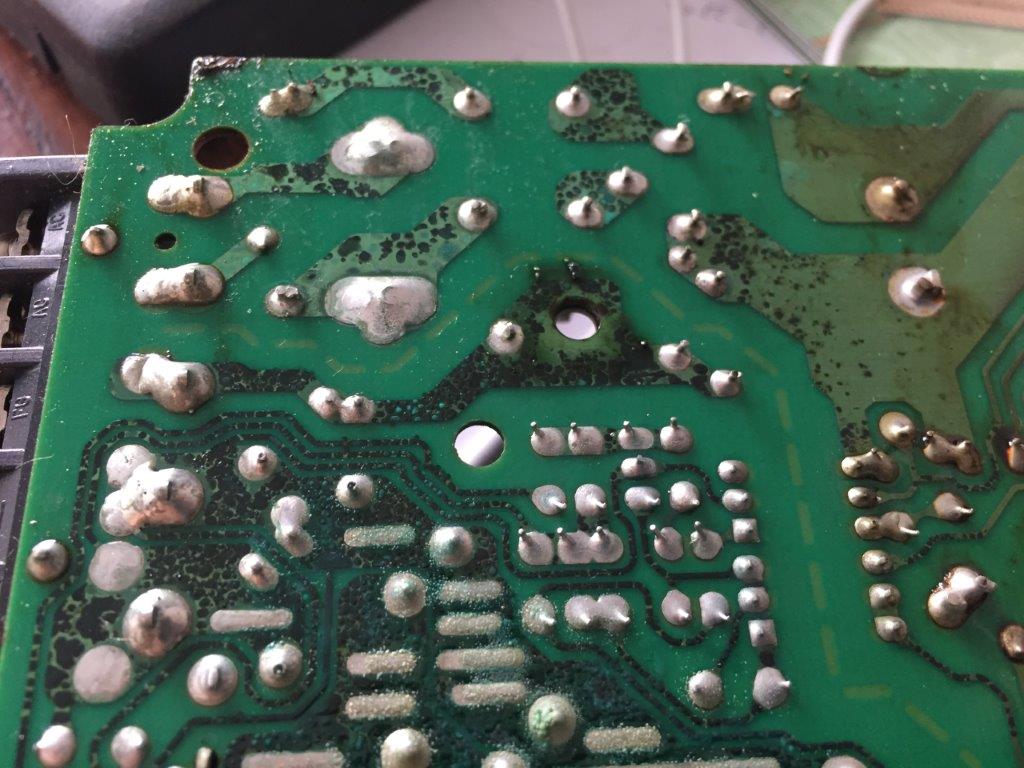

The (known) issue with the PSU was a leaking capacitor which had contaminated the bottom of the PCB. I could have cleaned it and recapped the supply but it looked a bit too degraded for my liking and I chose to replace it with a TDK Lambda HWS-30A-5 PSU. Ordered it, build it in and voila, we had a working sampler again.

I could have left the sampler in this (workable) state but I know defects bother me so started to work on the other issues as well. The display backlight was defective and replaced with a new EL foil from midi-rakete.de

The firmware was also a bit old (version 3.00) and as I was arranging 4.40 eproms, the dutch guy I got these from, also mentioned he had some scrap S1000 cases lying around. So I bought both the eproms and a used S1000 case from him (thanks, Karel Post). Swapped the eproms and moved all the electronics from the old to the new case (took me some time to do).

Last little task was to clean up the front input XLR connectors as they were corroded. I did managed to clean them with a Dremel and wirebrush but I might replace them with new connectors if this bothers me too much (ITT Cannon XLR3-31-F77)

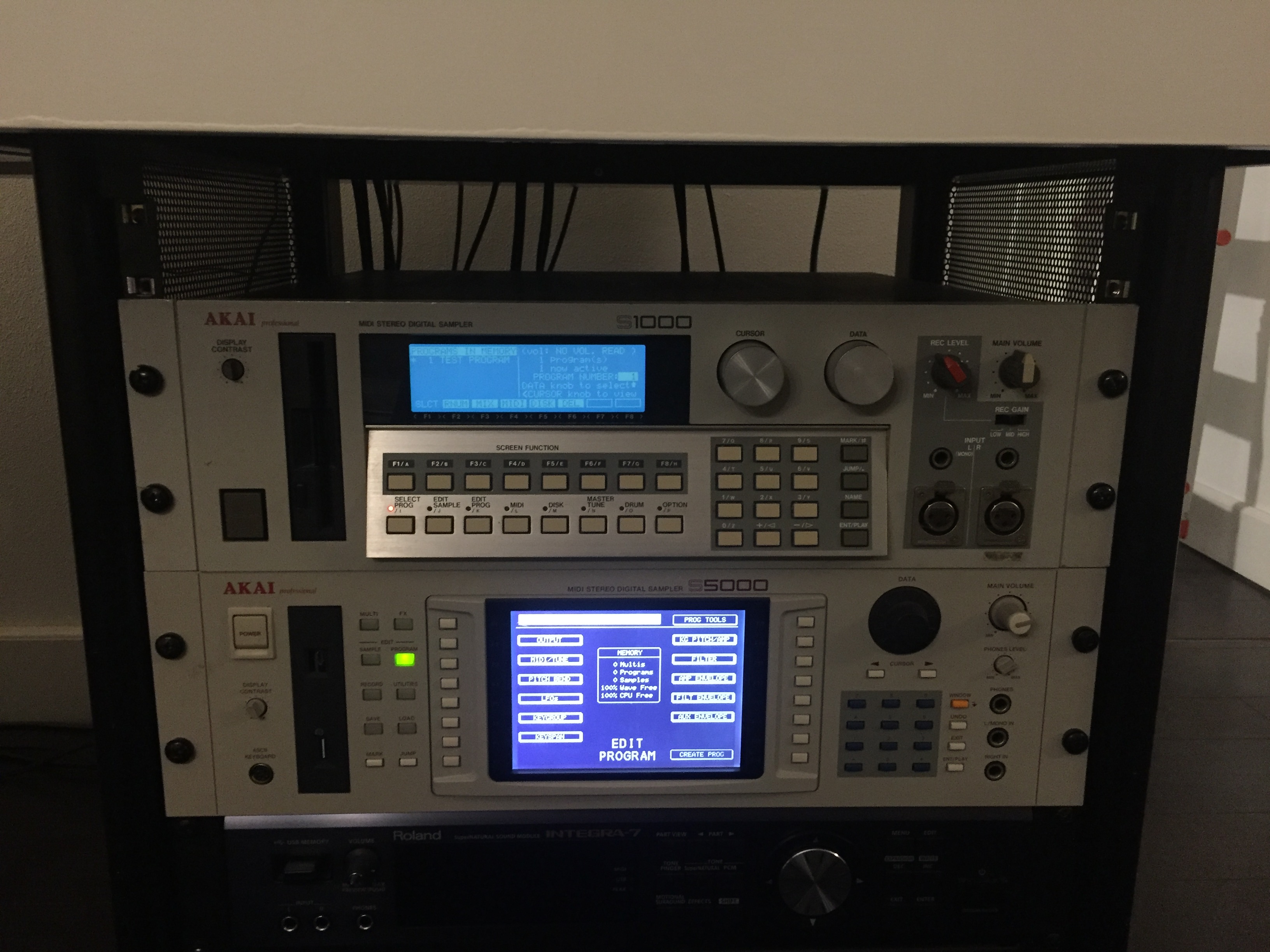

After the case swap and some final testing, it was time to join the S1000 with his younger S5000 brother 🙂